Description

UV-R is an innovative plug & play solution for curing UV paints. It is a compact, versatile, efficient machine, easily integrated even in complex finishing lines.

Available in different configurations to satisfy any type of curing need.

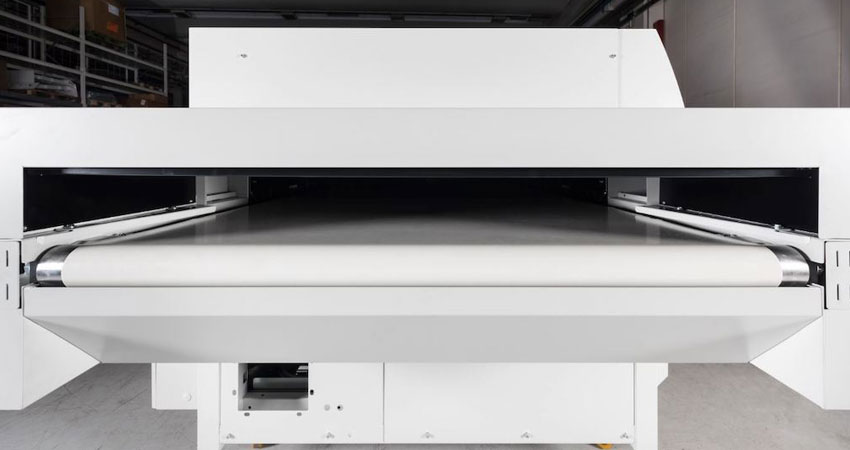

Conveyor System

UV-R can be configured with a slatted or belt conveyor, integrated in the framework of the machine.

Cooling System

UV-R ovens have an innovative laminar air flow cooling system (optional) incorporated in the lamp unit, able to disperse heat at the point of generation.

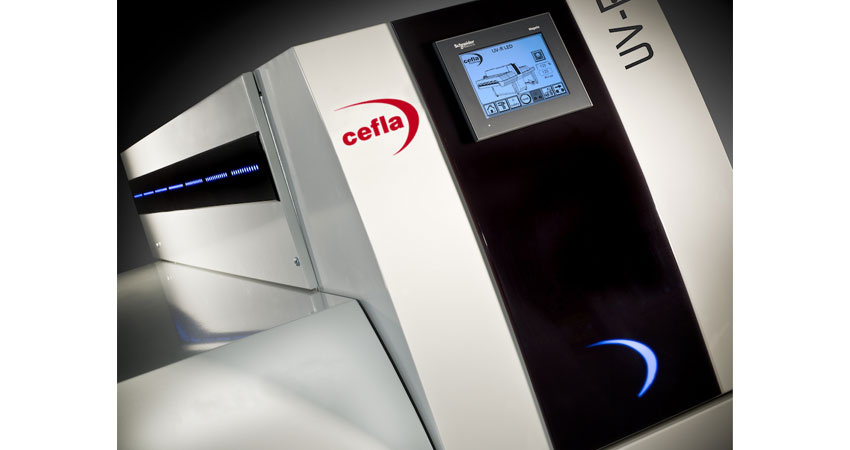

Control Panel

It is integrated in the machine body, requiring no additional space in the line layout.

Operator Interface

With its highly user-friendly interface, the touch-screen PLC integrated in the machine body allows quick, easy, direct control of all working parameters.

Energy Saving

UV-R has an electronic system for regulating the power of every single lamp, which also automatically activates the energy saving function by monitoring the presence of material under each lamp.

Configurations

- Underside UV-R: For complete cross-linking of the paint applied to the underside of the panel and/or of the overspray deposited in the recesses of panels with bas-relief shaping.

- UV-R SP: Also ensures cross-linking of the paint applied to the edges of workpieces with the aid of angled lamps and the delivery of more lamp energy to edges.

- UV-R Superfocus: This configuration is ideal for reducing the heating effect of the lamps on heat-sensitive materials (such as pine). The specially shaped lamp reflectors focus the UV beams in the same point of the panel, significantly reducing the number of lamps needed to cure the paint and avoiding beam dispersal. Space requirements and energy use are also reduced. This configuration can be integrated with the “SMART-THICK” workpiece thickness adjustment system, usually on roller coating lines

- UV-R LED: The UV-R LED configuration is recommended, combined with a traditional UV-R oven, for gelation and complete cross-linking of UV products on, particularly heat-sensitive substrates. UV-R LED is available in versions with 1 or 2 LED lamps, or in PLUS version (1 or 2 lamps) which combines LED lamps and traditional UV lamps in a single solution.

- UV-R PRO: UV-R PRO is the UV lamp oven which can be configured with lamps at the top and bottom, for curing moulding and narrow boards up to 300 mm wide.

Features

- Plug & play solution: space-saving and user-friendly

- Available in a large number of configurations for all curing requirements, for both roller and spray painting lines.

- The fastest, most versatile choice for curing UV paints. The long experience developed by Cefla Finishing in the field of ultraviolet ovens has years of constant innovation

- To the traditional oven UV-R we added other solutions providing the ideal solution for every application

- UV-R SUPERFOCUS, both in the roller lines and in the spray lines, can halve the number of lamps necessary for the drying of UV coatings thus minimizing the operating costs

- The system uses an electronic transformer controlled by PLC capable to continuously adjust the lamp power, recipe management and energy saving in case of workpieces absence

- UV-R LED: This technology, which provides a cutting-edge tool in a host of industries, is now able to meet any processing requirement. The LED is a source of very cold UV light that has considerable advantages for those substrates (such as pine) sensitive to temperature and therefore prevents overheating or damage of the workpiece. To ensure all customer processing requirements are met with, Cefla provides two versions of the UV-R LED: the LED and HYBRID versions

Materials:

- Wood

- Fibre cement

- Insulating materials

- Plastics