Description

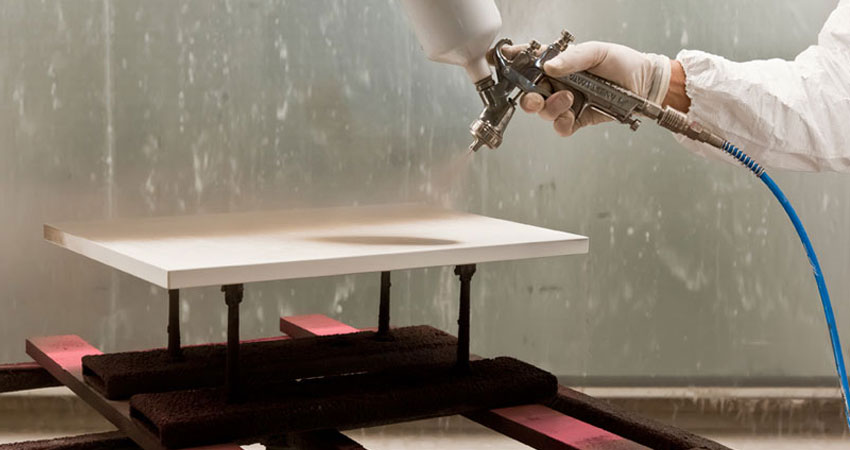

Our booths are designed to achieve end products of the highest quality. Many firms producing manufactured goods of the highest quality, where manual skills and professional expertise are essential factors, use Cefla booths (sometimes in combination with automatic coating plants to meet specific needs). We design and build our booths in full compliance with all relevant standards pertaining to noise, occupational health and safety, emissions, reliability and durability.

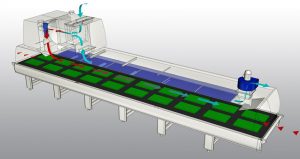

Configurations:

Dry spray booths

Dry spray booths are equipped with vertical front filters made of high-efficiency special papers and an internal horizontal polyester filter. The booths feature a centralised control panel complete with an energy saving device and an inverter for adjustment of the exhaust flow rate. The booth interior is suitably lit, in accordance with current regulations.

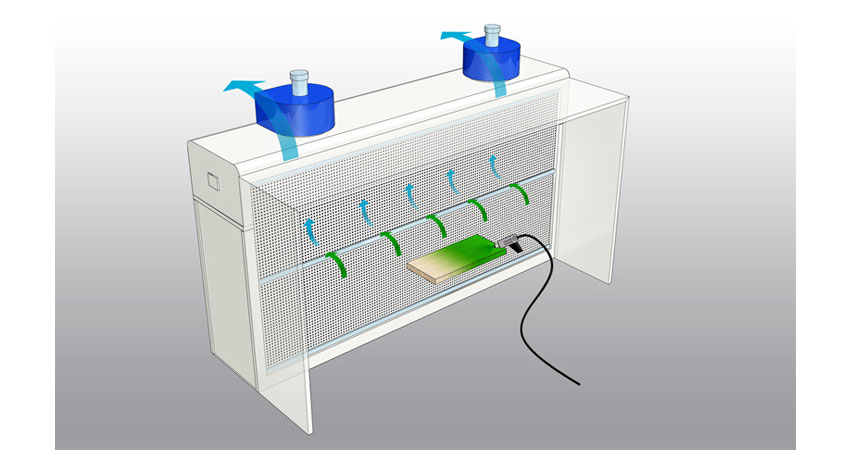

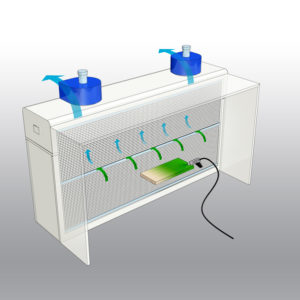

Water curtain spray booths

In this type of booth, overspray is filtered by a water curtain system consisting of two overlapping water curtains on two zinc-lined panels. The collection tank is designed to contain the minimum amount of water necessary, avoiding stagnation, waste and frequent replacement. It features a recycling pump and bypass for drainage, plus an automatic water top-up system. It is equipped with a centralised control panel and energy-saving device, combined with inverter-controlled regulation of the exhaust flow rate. The booth interior is suitably lit, in accordance with current regulations.

It is advisable to fit this type of booth with a water treatment system:

Big Bag Skimmer: filtered water is treated in a tank with the addition of flocculants, allowing solid particles to be separated from the water. The solid particles are collected using a scraper system, allowing the filtered water to be re-circulated.

Underground Skimmer: this static filtration system for separation of solid coating particles from water, consists of an underground collection tank for the water-coating mixture. Decantation is achieved using specific products that allow solid particles to be separated, guaranteeing the return of clean water to the tank.

Air make-up units: Air make-up units are an integral part of any coating or drying room. They are essential for guaranteeing that the air inside the room is correctly treated, by compensating, heating and filtering the exhaust air. Depending on requirements, a make-up unit can be equipped with bag or cartridge filters, with or without humidifier.

Hyperfilter: For special processes requiring absolutely no dust in the air, the most complete air make-up system is provided by a hyperfilter. Units of this kind are recommended in particular for machines and systems requiring controlled temperature and humidity conditions for spraying and/or drying extremely high quality finishes. This system is used, for example, for supplying in-line and vertical ovens, as well as pressurised spray booths and rooms. The delivery air passage chamber contains cylindrical cartridge filters designed to trap submicronic dust particles. The large filter surface ensures maximum efficiency combined with low maintenance requirements.

Features

- Spray booths constructed with the utmost respect for the environment and in compliance with relevant safety standards

- All configurations are equipped with an overspray recovery system

- All configurations can be equipped with the most sophisticated air filtration systems

- All the health parameters of spray environments (from lighting to humidity levels) are adjustable Cefla spray booths are the best choice for manufacturing firms that require the highest quality standards.