Description

Mito is the flexible, modular oscillating spray machine for small and medium outputs.

Reading Barrier

MITO is equipped with a high-precession photodiode reading barrier for scanning incoming workpieces. Precise scanning of workpieces’ size and the processing of their position by the control software allows spraying to be optimised, minimising the wastage of paint.

Spraying Arms

MITO can be equipped with 1 central or 2 side arms. The arms are able to manage colour/product change automatically and fast. Valve and time control can be handled directly by the software.

MITO is also suitable for glass. The MITO Glass configuration is absolutely the most flexible system for spraying on glass, since it is able to apply any type of paint. It is equipped with 1 special arm, which allows very fast automatic colour change, perfect for small production batches.

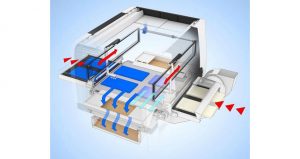

Overspray Filtration

Overspray is sucked through two-stage dry filters: the operating maintenance costs of this system are reduced to a minimum. The large filtering surface area guarantees better air distribution, which translates into uniform finishing and a cleaner machine.

Plenum

MITO has a patented “Airsphere” Plenum to guarantee a flow of perfectly clean air into the spraying zone, eliminating overspray residues during processing. The system ensures a high-quality finish.

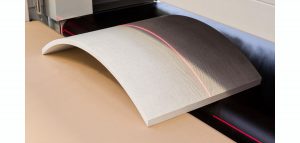

Conveyor System

MITO can be equipped with paper or carbon fibre belt (CFB) conveyor system. The paper conveyor is the perfect solution for glues and non-recoverable paints. The paper belt is completely taut at all times thanks to a vacuum system, which keeps the underside of panels perfectly clean as well as guaranteeing immaculate, uniform application on edge and face. It also has an automatic pay-off and take-up system for quick, convenient replacement.

The carbon fibre CFB conveyor is perfect for spraying any type of recoverable water or solvent-based paint. The CFB configuration is equipped with a patented HCD automatic recovery and cleaning system, which minimises maintenance procedures and solvent use. It also features a patented automatic belt centring system to ensure a perfectly stable working surface.

Control Panel

MITO has an electric control panel with PLC and machine control software, controlled by a 12.1″ colour touch screen.

Configuration

- SPRAYING ARMS: 1 or 2 arms; 1 arm for application on glass (Mito Glass)

- CONVEYOR SYSTEM: paper or carbon fibre (CFB)

Features

- Flexible and modular, perfect for small and medium outputs

- With patented Plenum for impeccable overspray suction

- Paper configuration ideal for glues and non-recoverable paints.

- The CFB configuration has patented automatic cleaning and belt centring systems.

Materials:

- Wood

- Plastics

- Metal

- Glass